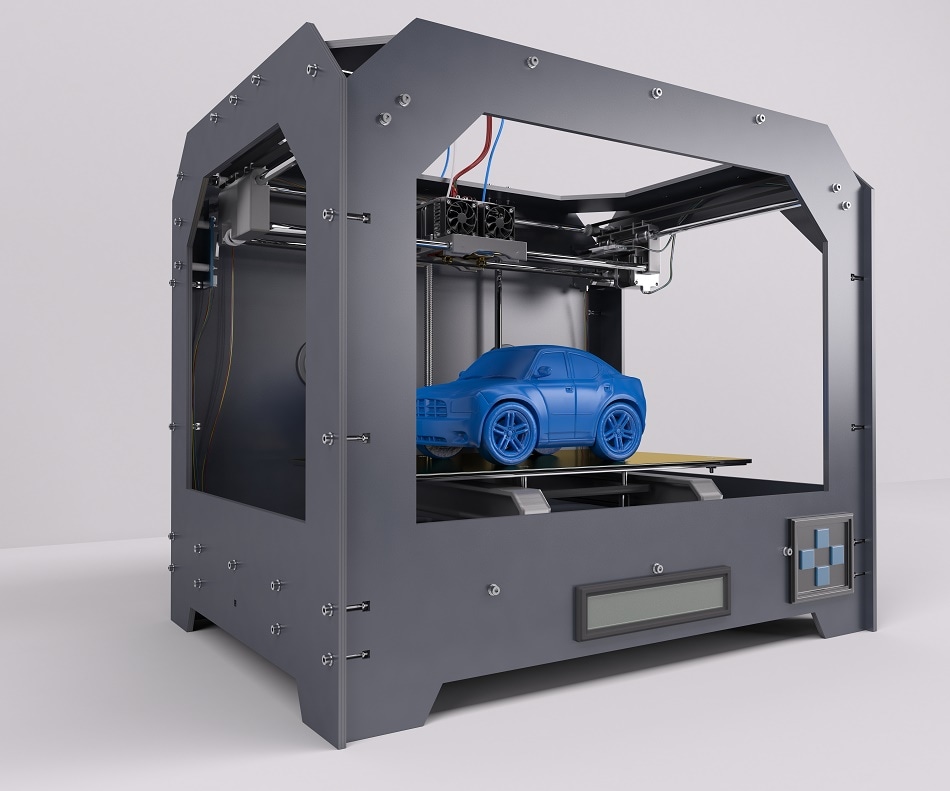

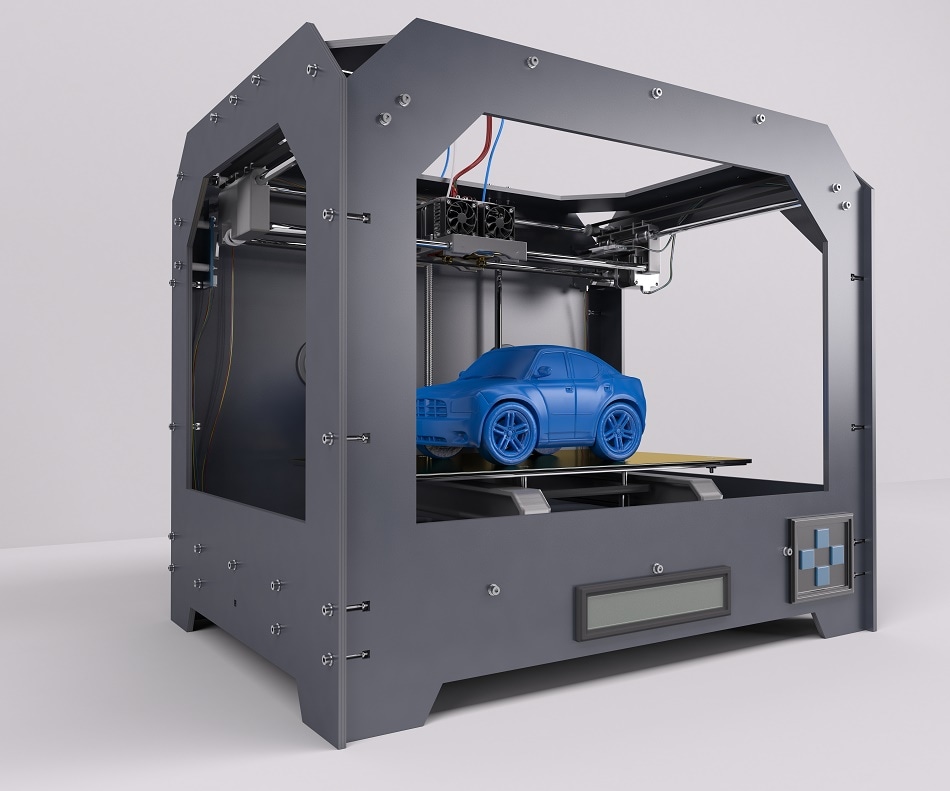

3D printing technology is amongst the numerous developments witnessed worldwide brought to action as a result of the continually expanding technology and the key advancements made in terms of its application. Ahead of its application in a plethora of end-use sectors, the 3D printing technology is cited as a significant asset for the automotive industry. The company serving the automotive sector are gradually moving towards effective technologies that aid in fast-pacing the automobile manufacturing process and meeting the changing consumer demands for next-gen vehicles. 3D has the capabilities to transform the way automobiles are engineered and designed and is gaining immense significance as it helps in minimizing the turnaround time, lower production costs, reduce material wastage, and boost the production rate. Automakers are able to enhance automobiles in terms of aesthetics and deliver working prototypes in the best turnaround time.

Redefining Automotive Manufacturing with 3D Printing Technology

3D printing has helped automakers in redefining the process of manufacturing automobiles as it brings to the table, both efficiency and speed. Automakers are largely considering this technology to transform the way vehicles were engineered conventionally. Leading automotive companies are making use of 3D printing technology in automotive production.

For instance, Audi AG, a Germany-based automobile manufacturer was recently witnessed expanding the utilization of 3D printers in automotive manufacturing. The 3D printers locally printed auxiliary and custom-designed tools aid employees working on the automotive production lines. Ahead of this capability expansion, the company planned to set up a distinct department assigned for implementation at the Neckarsulm-based site. The analysis center team decisively established polymer 3D printing in the craft-scale R8 factory at the Bölllinger Höfe production site. This team puts together several ideas for new or enhanced tools in collaboration with the production line employees. The establishment of a distinct specialist department for 3D printing professionalizes the already successful project. Production line employees are directly involved in the development process of 3D printed tools.

Metal printing has been a hot topic across the globe, with major emphasis on mass production. Companies providing 3D printing technology are expanding their business towards metal printing considering the rising demand for 3D printed automotive components. Aligned with this, HP, a global printing giant recently entered in the market with the introduction of its Metal Jet 3D Printer. With the company enables mass production for mainstream metals, steels in particular. Furthermore, HP has signed deals with leading metal producing partners and its customers include Johnson & Johnson Medical Devices and Volkswagen

Manufacturers Put Faith in 3D Printing to Accelerate Mass Production

Companies are centering their efforts on mass production of vehicles owing to a plethora of benefits including optimized assembly lines, lowered labor costs, and others. This mass production is made possible with the use of automation across the automotive production line along with the utilization of next-gen technologies such as 3D printing. From its use for rapid prototyping for automotive designs to manufacturing serial automotive parts for the production assembly line, 3D printing technology has come a long way.

Moreover, 3D printing capabilities further support the emergence of electric mobility. An Italy-based start-up company, -X Electrical Vehicle (XEV) in collaboration with Polymaker, a Chinese firm recently planned to unveil the first electric car in China in the second quarter of 2019. These low-speed electric vehicles would be manufactured using a 3D printer in mass production fashion that would enable almost entire production in a span of three days. The production would commence in a mega factory based in

Jiangsu—

China.

Beyond Manufacturing: What More Does 3D Printing Bring to the Table?

Ahead of manufacturing, 3D printing technology has the automakers’ back for providing value-added services. Companies are able to expand their efforts in the right direction with the help of 3D printing.

For instance, Mini, a British car manufacturer begun offering Mini Yours personalization service for its customers that allows them to personalize their vehicles with the help of laser engraving and 3D printing. 3D printing provides automakers the capability to produce parts tailored to consumer needs On account of this, Mini is providing high-level customization with the new service, having a primary focus on 3D printing.

Industry News

Industry News