Industry News

Industry News

Steering gear can generate undesirable noise particularly in electric cars. Schaeffler now provides a solution to this problem in the form of a swivel bearing. It is equipped with a specially curved “spherical cap” (ball socket) and is able to tilt within itself and thus compensate the swiveling of the worm shaft.

Electromechanical assisted steering has become indispensable in modern vehicles because these systems help to save fuel and increase comfort at the same time. Many drivers appreciate a smooth-running steering system particularly during maneuvering and parking or are already using fully automatic parking aids. However, steering gear can generate undesirable noise particularly in electric cars. Schaeffler now provides a solution to this problem in the form of a swivel bearing.

Four different steering systems in use worldwide

Today, four different steering systems are used worldwide. Electric motors are arranged in parallel to the toothed rack for the greatest level of steering torque assistance in heavy-duty vehicles, SUVs, and small trucks. These electric motors drive a ball screw drive by means of a belt. The spindle of the ball screw drive is connected directly with the toothed rack. Such systems are called Rack Electric Power Steering. Schaeffler can offer and supply a range of different ball screw drives for these steering systems from its own development and production facilities.

In smaller and lighter vehicles, the steering column is electrically assisted (Electric Power Steering column, EPSc). Medium-duty and heavy-duty vehicles use an electrically assisted system on the toothed rack, directly on the pinion of the mechanical steering gear (Electric Power Steering single pinion, EPSsp). In these vehicle classes, an additional electric gear unit can also be installed on the toothed rack, which transmits steering torque to the toothed rack via a second pinion (Electric Power Steering dual pinion, EPSdp). Power steering assistance is provided by an electric motor that transmits steering torque via a worm shaft gear unit either directly to the steering shaft on the steering column (EPSc) or directly to the toothed rack (EPSsp and EPSdp).

Optimized swivel bearing reduces friction and noise

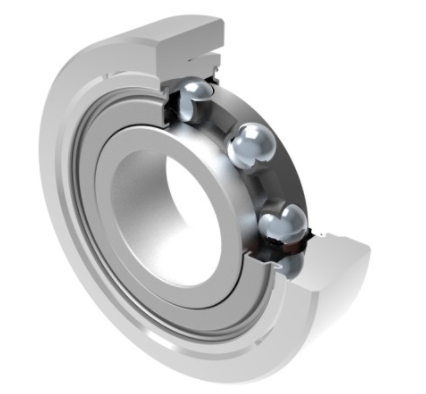

Various requirements are placed simultaneously on the swivel bearing in these steering systems with worm shaft gear units. Firstly, the swivel bearing supports the worm shaft as a locating bearing and must support the axial and radial forces that occur. Secondly, the swivel bearing must counteract the generation of noise in the system. This is due to the fact that the worm shaft transmits the torque of the electric motor via helical teeth to the worm gear, resulting in a vertical motion of the worm shaft that causes the swivel bearing to tilt. A conventional ball bearing would have increased running noise and increased frictional torque under these conditions, which would have a negative effect on the performance of the gear unit.

For this reason, Schaeffler has now optimized the swivel bearing and equipped it with a specially curved “spherical cap” (ball socket). Thanks to this design, the bearing is able to tilt within itself and thus compensate the swiveling of the worm shaft without generating increased frictional torque and noise. A further advantage is that the worm shaft can be radially preloaded so that no clearance results between the worm shaft and the worm gear. This reduces so-called “clatter” – a clattering sound that is caused because the rotation direction of the worm shaft changes every time the steering direction changes and the opposing tooth flanks come into contact. The swiveling motion of the newly designed bearing also compensates misalignments in the housing.

Solutions for electric mobility – down to the smallest detail

Because drivers are now used to high levels of auditory comfort in the interior of vehicles, noise can be regarded as annoying particularly during maneuvering and parking when assisted steering is required. This applies especially for automatic parking if a number of steering movements are carried out in quick succession and for electric vehicles, in which no engine nose covers up other noise and vibrations. With its new swivel bearing, Schaeffler is once again demonstrating that the company wants to help electric mobility gain wide acceptance – not just with large solutions such as electric drive systems, but also down to the smallest detail.