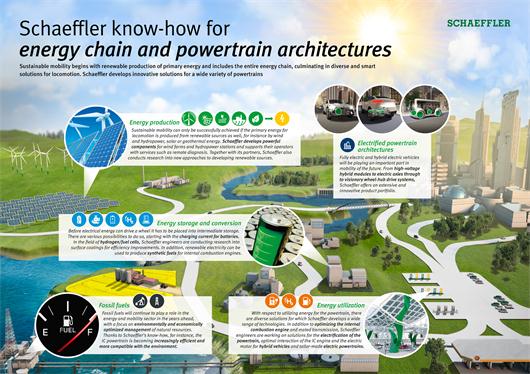

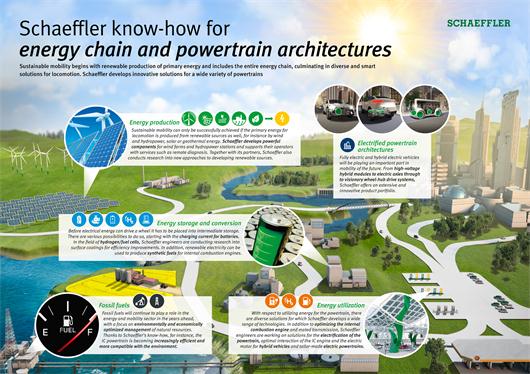

The objective is CO2-neutral mobility. On the way to achieving this goal, the automotive sector can choose from a wide spectrum of drive options. Schaeffler relies on hybrid technologies using an efficient internal combustion engine, purely electric drives, and an environmentally-friendly and sustainable view of the entire energy chain (“well-to-wheel”) for the development of customized system solutions for the electrified drive train.

The envisioned ideal solution is a climate-neutral vehicle that is powered by renewable energy sources. “Such a radical transformation will not be accomplished overnight,” explained Prof. Peter Gutzmer, Chief Technology Officer at Schaeffler, at the 16th CTI Symposium in Berlin. In his speech, he placed particular emphasis on the integrated analysis of energy and drive options for future mobility requirements.

As an automotive supplier, Schaeffler relies not only on high-end engineering technology for electric drive systems, but also on advanced expertise in products for transmission systems and efficient internal combustion technology. “It is all about cutting emissions worldwide – now. To this end, we must also develop cleaner internal combustion engines,” added Prof. Gutzmer. He continued emphasizing: “This change and comprehensive security of supply can only be accomplished by intelligently combining different energy sources and drive topologies with each other.”

Mobility can only be sustainable if the entire energy chain is considered: from the generation, conversion, and storage of energy through to technical solutions for a wide range of drive trains (“well-to-wheel”). For example, based on the current electricity mix within the European Union, an electric vehicle still emits 65 percent of the CO2 quantity of a comparable vehicle with a gasoline engine. By contrast, if the electric vehicle is charged entirely using electricity generated from renewable sources, the CO2 emissions fall to a mere three percent compared to conventional vehicles. This clearly shows that sustainable mobility can only be successful if the primary energy source for ensuring movement using different drive concepts (BEV, FCEV, ICEV, PHEV, synthetic fuels) also comes from renewable sources.

Customized system solution for the electrified drive train

Schaeffler set the course for the age of electrified drive architectures with hybrid products for transmission applications and the start of its research and development activities at the end of the 1990s. Today, the company has a wide portfolio of electric mobility products. Schaeffler products ranging from hybrid modules and the electric axle through to the wheel hub drive can be integrated into hybrid vehicles and all-electric cars. Systems such as the E-clutch facilitate, for example, the start-stop and sailing functions in manual transmissions in combination with hybridization in the belt drive. Thus, CO2 emissions can already be reduced by up to 10 percent under real operating conditions.

With the electric axle, Schaeffler has developed a modular system solution for hybrid vehicles and all-electric cars. The product range starts with electric axles with single-speed ratio in a coaxial or parallel axis design. The planetary design of the differential results in an extremely compact transmission with plenty of space for the electric motor, which can be a PMSM (permanently excited synchronous motor) or an ASM (asynchronous motor) with or without power electronics. The basic configuration can be extended by adding functional elements. In this way, it is possible to integrate functions such as a parking lock.

A second gear is often required, particularly in plug-in hybrid vehicles where dynamic, fully electric operation up to 120 km/h and a high final speed are prerequisites. The two-speed axle developed by Schaeffler enables lateral dynamics to be improved using a torque vectoring component. This function is ensured by integrating an appropriate transmission and an electric motor designed for seven kilowatts.

The efficiency and thus the fuel economy of hybrid vehicles with drive architectures comprising an electric motor, power electronics, a battery, and a supplementary internal combustion engine are dependent on the perfect interaction of all components. Schaeffler’s decades of expertise in systems and components represent significant added value for customers in this field. In addition to the mechanical design of the electric drive systems, electric vehicles also require power electronics. Schaeffler offers power technologies with an optimized design envelope, which enable efficient conversion, control, and integration of electrical energy into the entire system.

Industry News

Industry News