Regal Beloit Corporation, is a leading manufacturer of electric motors, electrical motion controls, power generation and power transmission components.

Unplanned outages due to mechanical failures can cost millions of dollars of lost production time to Oil and Gas companies. While itвҖҷs difficult to quantify the cost of unplanned downtime, an outage of a single day may exceed ~$6.5M, for the average U.S. refinery1. The shift from Reactive Maintenance (RM) to data driven Proactive Maintenance (PAM) strategies can not only reduce lost revenue from unplanned outages but reduce the overall costs associated with operating and maintaining plant equipment by 60%2.

Disc and diaphragm couplings are not a вҖңwear itemвҖқ like the seals in a turbine or compressor, which can cause a decrease in equipment performance and are typically replaced on a time-based schedule. Most high performance couplings are designed to be maintenance free, and if they are operated within their rated capacities, can outlast the equipment to which they are connected3. To maximize production, each asset, critical or not, should have an appropriate maintenance strategy that is followed, audited for effectiveness, and adjusted as necessary to ensure reliability.

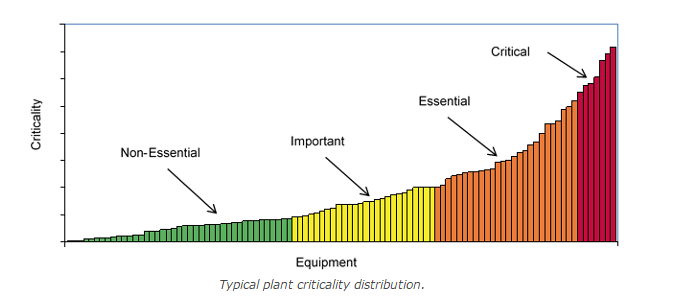

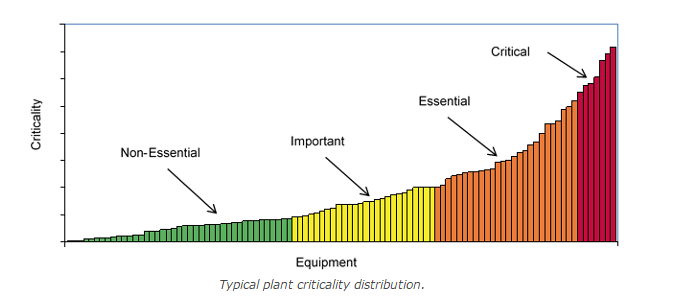

Criticality is a quantitative ranking process based on: operational cost, maintenance cost, throughput losses, quality, safety, and environmental implications. The graph below represents the criticality distribution of the equipment at a typical plant (Figure 1). Only 10% of the equipment at this plant is deemed critical due to the costs incurred if placed out of service. 25 percent can be defined as essential. 30 percent is important. The remaining 35% is non-essential. Each criticality level can be paired with an effective maintenance strategy to balance the cost of implementation with the required reliability levels.

Following a criticality analysis, a Failure Mode and Effects Analysis (FMEA) is conducted to determine all the potential failure types, what the failure effect is, and what can be used to mitigate or eliminate the failure mode. The FMEA is then used as the foundation in the decision-making process to determine the correct maintenance strategy for new equipment. The most common maintenance strategies are listed below.

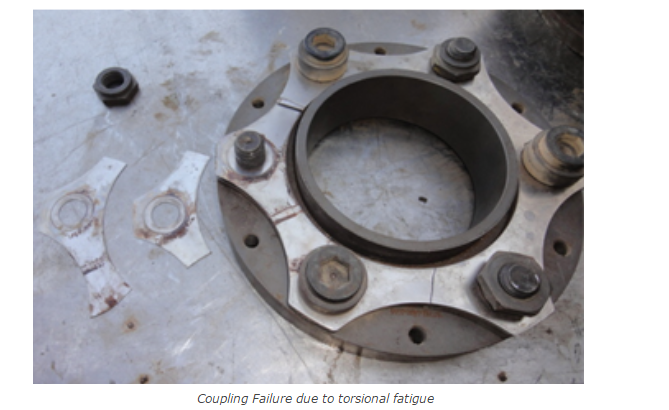

Disc and diaphragm couplings are designed for infinite life when operated within their application design limits; however, a change in operating conditions may a couplings service life4. The following sections highlight potential failure modes which can be mitigated or eliminated through the Kop-Flex® Factory Recertification service. Used couplings are reconditioned to like вҖңLike NewвҖқ condition and returned with the original factory warranty, for a significant value over buying new5.

While recertifying high performance couplings during every turnaround would be the most conservative maintenance strategy, it may not be the most cost effective or feasible due to scheduling logistics. Guidelines which combine Factory Recertification and condition monitoring, with the understanding and prevention of past issues, yields an effective Proactive Maintenance strategy for your critical rotating equipment6. The following sections provide a foundational understanding of the Factors which may result in the reduction of the couplings effective service life.

Misalignment

While misalignment is typically not measured while equipment is in service, it is helpful to be aware of a few troublesome variables which can reduce the service life of the coupling. One of the most common questions regarding coupling alignment pertains to thermal offsets while operating. If the equipment and coupling are subjected to large temperature differentials, the accuracy of the thermal growth values is extremely important. Was a hot alignment check of the equipment performed to mitigate against the unquantified movement between shafts and confirm the supplied values? Other difficulties in the determination of alignment while in operation may be due to a shifting foundation or pipe strain. Vibration monitoring or Root Cause Analysis (RCA) of a failed coupling can greatly assist in the identification and resolution of these issues. Factory Recertification can be utilized to reset the damage accumulation the coupling may have endured and return it to its вҖңlike newвҖқ condition.

Environmental

Another factor which should be considered is the operating environment of the coupling. For many offshore applications, salt water results in a highly corrosive environment which can accelerate the oxidation of ferrous metals. In some applications, the couplings are operated at temperatures well above the design rating due to guard design and unforeseen field issues. This higher temperature can affect the service life of the coupling. If these, or other environmental factors are true, the equipment inspection frequency should be adjusted accordingly. Factory Recertification returns the couplings service factor to the original, вҖңas designedвҖқ value.

Equipment and Operating Conditions

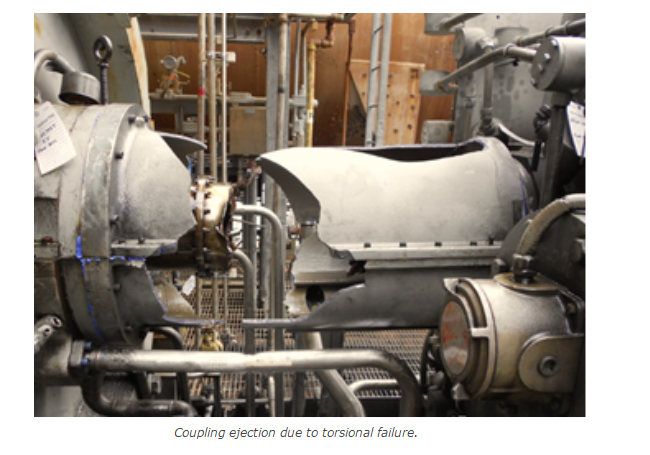

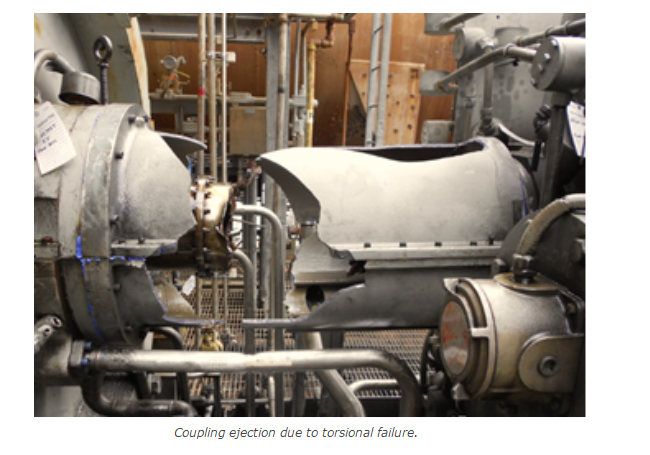

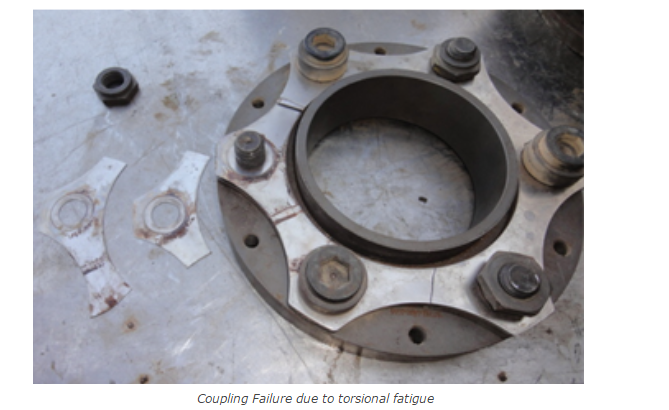

Simulation of the torsional vibration response of a drivetrain is a critical analysis technique because it allows for the evaluation of transmitted torques during the equipment design stage. Since some degree of uncertainty is present within the results of the model, API standards require a 10% separation margin from any excitation frequency. While better data and modeling techniques have increased the accuracy of the torsional systems, problems may persist, resulting in undamped torsional vibration which may damage the equipment.

Additionally, if the equipment is subject to an irregular operating schedule, the coupling may experience a high magnitude transient torque with each startup. Improper tuning of VFD controlled motors may subject the coupling to damaging torsional oscillations which werenвҖҷt accounted for in the design phase, thereby shortening the usable life of the coupling and possibly the equipment.

Process Conditions

The usable life of the coupling may also be reduced by variations in the process conditions. Has a compressor been subjected to known surge events? Perhaps the equipment train does not run as smoothly as expected due to the process flow pulsations or the unexpected excitation of a system natural frequency. These events are typically identified using Condition Monitoring techniques it is typically not possible to determine how they could affect the coupling load case.

Summary

Couplings are designed to be the weakest link and lowest cost component on rotating equipment. They are often overlooked because of this, but frequently provide insight into the equipment operating conditions. The cracked outer discs of a disc coupling may tell you whether the equipment is operating under excessive misalignment and the excitation of a resonant torsional frequency may cause fretting in the center of a disc pack. If these issues remain unknown and arenвҖҷt addressed, there is an increased risk of equipment failure as well as the associated unplanned downtime and lost production.

Consider this scenario, Plant A and Plant B are operating identical steam turbine driven compressor trains since they were commissioned seven years ago. In Plant A, the coupling has been operating continuously with low vibration since startup, while in Plant B, the train has a history of issues causing shutdowns and operates with higher vibration attributed to misalignment due to thermal expansion. While both plants should include the coupling in the applicable maintenance plan for its parent asset, there is a higher probability of failure for the coupling in Plant B due to the additional loading itвҖҷs been subjected to while in service. Assuming the equipment train in Plant B costs ~$20M, the cost of a coupling recertification during the second turnaround at 14 years, is a small price to pay for assured continual performance.

The previous sections cover a few possible failure modes which can be mitigated through Kop-Flex® Factory Recertification service. These items can provide a foundation of questions to ask about your equipment to determine the proper maintenance schedule for the equipment and application. As an initial step, using the Preventative Maintenance intervals of the other equipment on the train provides an ideal time to inspect the flexible coupling. Depending on the risk factors of a specific train, Factory Recertification may be the best practice to achieve maximum uptime of your equipment.

Industry News

Industry News