A telescope is under construction in Chile that promises to provide an entirely new way of looking at the universe.

On a ridge in Chile, a new telescope now under construction, the Large Synoptic Survey Telescope (LSST), will be able to capture more detail from faint astronomical objects than any existing optical telescope, and in the process change the way we view the universe.

The design of the LSST is revolutionary, combining an innovative three-mirror complex with an exceptionally wide field of view – the equivalent of 40 full moons – that will feed back to the largest digital imaging camera ever constructed. The telescope will deliver an entirely new way of looking at the cosmos.

SKF hydrostatic bearing system

SKF’s hydrostatic bearing system (HBS) custom hydrostatic shoe bearing solution for the LSST has been developed for azimuth/elevation axes and rotation to meet accuracy, high stiffness and minimum friction demands. The HBS is self-aligning and highly accurate with low friction (zero starting friction) and mount stiffness to counter seismic shocks. The system can accommodate extremely heavy loads and operates without wear.

The LSST is being built to conduct a 10-year survey of the universe, gathering some 60 petabytes (a petabyte is a million gigabytes) of information in the process. This information will be made available to astronomers, educational institutions and the public, making it possible for anyone to view objects 10 million times fainter than what can be detected with the human eye.

Sited in the Cerro PachĂłn ridge in the Coquimbo region of Chile, the LSST will capture more than 800 panoramic images nightly, each of which will be recorded on a 3.2-billion-pixel camera. Every three nights it will produce an animated, three-dimensional cosmic map of the visible sky. Applications of the data captured are almost unlimited. They include enhancing our understanding of dark matter and dark energy, tracking transient objects, exploring remote solar systems, mapping the op-tical sky, exploring the formation and structure of our own galaxy and even detecting and tracking hazardous asteroids that could potentially hit the Earth. The information collected, more than 15 terabytes nightly, will be processed by the National Center for Supercomputing Applications, situated at the University of Illinois at Urbana-Champaign in the United States. From there, relevant information will be fed to optical telescope sites better equipped to observe individual events and objects.

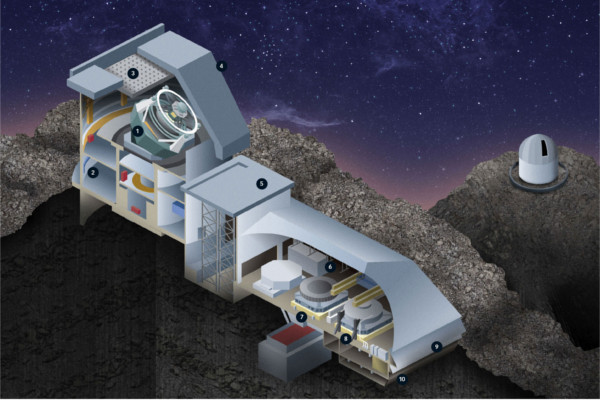

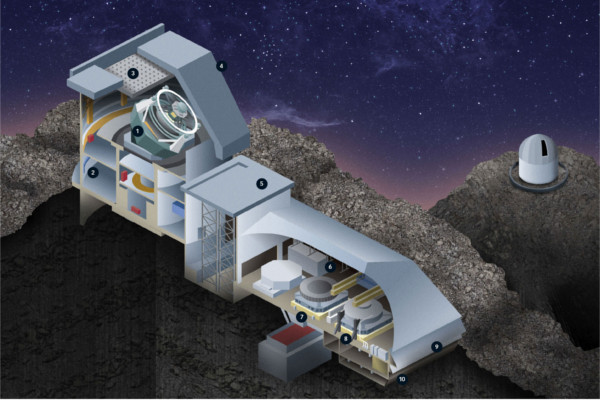

LSST main parts

1. 350-tonne telescope

2. 16-metre-long tele-scope pier

3. 11-metre-wide wind/light screen

4. 30-metre-high dome

5. 27-metre-high vertical platform lift

6. camera clean room

7. 75-tonne M1M3 tele-scope cell

8. coating chamber

9. control room

10. machine shop

The fundamental design concept is straightforward: to provide a frequent deep surveying of the whole visible sky over a 10-year period, creating the largest astronomical catalogue of images and data in existence. Spanish engineering company Empresarios Agrupados (EA), which has a proven track record in large telescope facilities, particularly the GranTeCan telescope on La Palma in the Canary Islands, was commissioned to develop and supply the detail design and engineering and to manage manufacturing, construction, erection and testing of the LSST mount assembly. The telescope is being manufactured at the Asturfeito steel facility in Asturias, Spain.

Alfredo Orden, head of the components section in the EA mechanical department, leads a team of 20 engineers specialized in mechanical engineering, control systems, electrical engineering, construction and layout. “There are a number of challenges that we have faced with the design of the LSST – supporting an 8.4-metre-diameter mirror assembly and a three-metre digital sensor, designing a structure that will withstand the frequent seismic shocks in this part of Chile and making sure that the whole assembly moves with pinpoint accuracy and has minimal downtime and maintenance requirements,” he says. “All these factors require the highest standard of engineering design.”

But Orden seems to take the scale and complexity of the project in stride. “Engineering is engineering,” he says. “We solve engineering problems. The biggest challenges are how to be competitive. The size and scope of any project is decided by the limits of the engineer’s imagination and intelligence. Our approach here is to maintain a working atmosphere with a constant dynamic interchange of ideas. The reliability and precision of the LSST components are critical to its successful functioning. It’s our job to make sure that all the design elements – procurement, construction, installation and seamless functioning of all mechanical and electrical systems – are perfect.”

Industry News

Industry News