At the EMO 2017, Schaeffler will be presenting mechanical components, electric drives, and digitally supported solutions that will ensure considerably more productivity, availability, and quality for the next generation of machine tools – whether it’s for main spindles, feed axes, rotary axes, or rotary tables. One trend is clear – the number of components equipped with sensors in the Schaeffler product range is constantly increasing.

The driving force behind all new Schaeffler developments is to further increase customer benefit. This is why an increasing number of the company’s purely mechanical products are being integrated into the digital world. Thanks to the digitalization of bearings, it is possible to make optimum use of machine processes to achieve the maximum degree of capacity utilization, to improve product quality, and to extend the life of the machine. Having said this, there is still significant room for progress in terms of the innovative materials and manufacturing methods available for rolling bearings, which the following examples will demonstrate.

Higher speeds, longer operating life, greater precision

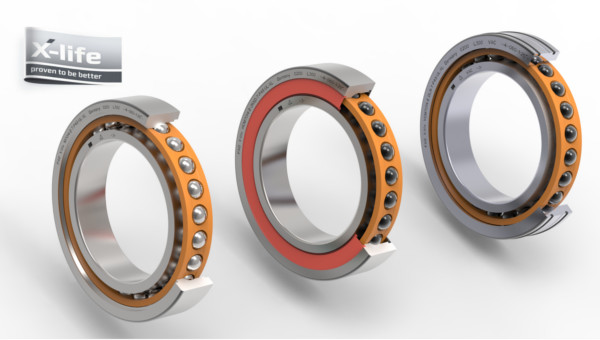

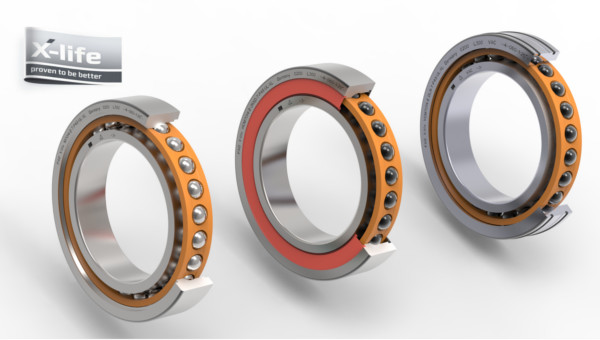

In Hanover, Schaeffler will present a total of four new bearing series in X-life quality: The new M-series FAG High-Speed spindle angular contact ball bearings, the N10 and NN30-series FAG high-precision cylindrical roller bearings, the six-row INA linear recirculating ball bearing and guideway assemblies (KUSE) for linear axes, and the INA YRTC rotary table bearings. These new X-life bearings offer the machine tool construction sector optimum values in terms of limiting speeds, carrying capacities, as well as rigidity and operating life.

There is an extensive product range on offer for driven rotary axes and rotary tables that leaves nothing to be desired. The portfolio includes three rotary table bearings with and without integrated measurement systems as well as three torque motor series from INA Drives & Mechatronics (IDAM). A further highlight from IDAM is the new SRV torque motor series for machining accuracies in the sub-micron range.

Vacrodur, a rolling bearing steel that is manufactured using powder-metallurgic methods is an entirely new development. It has an extremely high load carrying capacity, is wear-resistant and can withstand very high temperatures of up to 400°C with no loss of hardness. It was specially optimized for the operating conditions of the M-series High-Speed spindle bearings.

The M-series High-Speed spindle bearings in X-life quality are characterized by an optimized internal construction with balls of a mean diameter. They therefore combine the high speed capacity of bearings with small balls with the robustness and load carrying capacity of large-ball bearings. The series will be available in the three different versions: M, HCM, and VCM. M-series spindle bearings are manufactured entirely from 100Cr6, whereas HCM-series bearings are equipped with ceramic balls. Spindle bearings in the VCM High-Speed series also feature balls made from ceramic material, but with bearing rings made from the newly-developed Vacrodur high-performance material. VCM-type spindle bearings specifically open up entirely new levels of freedom when designing motor spindles compared to conventional spindle bearings.

Mechatronic systems against premature and unplanned machine downtimes

Schaeffler’s Linear Technology is presenting a linear recirculating roller bearing and guideway assembly with condition-based automatic relubrication. For this purpose, the guide carriage is equipped with new sensor technology that has been developed in-house. The integrated sensor, electronic evaluation, and relubrication systems form a control loop that ensures intelligent, requirement-based relubrication. This system ensures optimum lubrication conditions in the linear guidance system and, in turn, prevents lubrication starvation and overgreasing. Furthermore, if the guide carriage becomes contaminated with foreign bodies or liquid, the system triggers additional lubricating impulses. This means that initial damage can be prevented from the outset. The unplanned downtimes of machine tools caused by lubrication starvation in linear guidance systems are prevented, machine running times are increased, and manufacturing quality remains constant.

An entirely new system that protects the motor spindle bearing support from overloading will also be presented for the first time. This innovative system records the loads occurring in a spindle bearing using a sensor ring and emits a warning signal before the spindle bearings are damaged as a result of continuous overloading or drastically increasing loads. By directly measuring the deflection and tilting of the front spindle bearing under load and speed, it is also possible to immediately deactivate the spindle in the event of a collision.

At the EMO 2017, Schaeffler will be presenting the prototype of a multi-channel condition monitoring system (CMS), which was specially configured for monitoring several subsystems in machine tools. The CMS enables the condition analysis and condition predictions of entire machine tools, particularly for main spindles, feed axes guidance systems, and rotary axes. The condition monitoring system is available to customers as a test system.

Technical information available everywhere

Schaeffler now offers several apps for mobile communication that have been designed for customers, engineers, sales partners, and mounting technicians in the machine tool construction sector. The PrecisionDesk app, allows bearing-specific measurement reports for spindle and rotary table bearings to be accessed and stored by scanning the data matrix code (DMC) on bearings and bearing packaging. Schaeffler will also be exhibiting the prototype of a Desktop version at the EMO, which enables the reports for mounting, for example, to be further processed.

Bearing solutions up close

Visit the Schaeffler stand (Hall 7, Booth C42) and see for yourself the progress that has been made in terms of new products, system solutions, and services. Our engineers will be more than happy to explain how Schaeffler’s bearing solutions make machine tools more productive, more precise, and more durable.

Industry News

Industry News