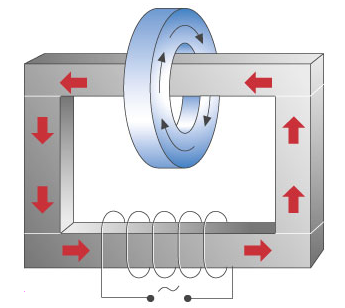

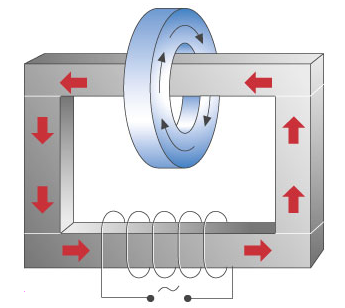

An induction heater can be compared to a transformer using the principle of a primary coil with a large number of windings, and a secondary coil with a few windings, on a mutual iron core. The input/output voltage ratio is equal to the ratio of the windings, while the energy remains the same.

Consequently, the secondary coil will provide a low voltage at high amperage. In the case of an SKF induction heater, the bearing is a short circuited, single turn, secondary coil through which a low A.C. voltage flows at high amperage, thus generating high heat. The heater itself, including the yoke, remains at ambient temperature.

As this type of heating induces an electric current, the bearing will become magnetised. It is important to ensure that the bearing is then demagnetised so that it will not attract metal particles during operation.

All SKF induction heaters are equipped with automatic demagnetising cycles.

Industry News

Industry News