Design engineers across industries rely on pillow block bearings for a variety of tough and unconventional applications. Having access to data that backs housing strength performance claims is an integral part of choosing the right bearing to keep operations running optimally.

What design considerations must be made when the application demands a pillow block installation on a non-horizontal orientation? What happens when bearing load is not applied through the base of the unit? Timken answers these questions with physical testing, advanced modeling and real-world experience to facilitate the selection of pillow block bearings for specific applications.

Why Strength Matters

The roller bearing is an essential component of countless industrial applications around the world. The reliability and repeatability of the processes where differing types of roller bearings provide functionality is important.

For most industrial operations, designers seek to maximize uptime with the selection of components that offer extended service life. In most applications where rolling-element bearings are applied, bearing static and dynamic load capacities are crucial parameters:

Static load rating: The maximum load a bearing can withstand before permanent damage to the raceways or rolling elements; indicates a load being applied in a constant, unchanging direction under non-rotating conditions.

Dynamic load rating: The radial load under which a population of bearings will achieve an L10 of one million revolutions. The load value is used to estimate bearing life based on the actual applied loads and speeds.

For pillow block (also known as plummer block, mounted bearing or housed unit) applications, the strength rating of the housing itself is a critically important performance attribute—and is why Timken performed an evaluation of housing strength and permissible load across its roller housed unit product line.:

Solid block housings: One-piece housings that are factory assembled, pregreased and sealed, offering simple installation direct from shelf to shaft. Split block housings: Two-piece housings that are split in the middle with bolts fixing the two halves. These allow for simpler installation, and replacement of the bearings and seals without removal of the housings.

Industrial operators rely on these specialty bearings and housings for supporting shafts, gears and other rotating or oscillating components in a variety of unconventional loading orientations. Also, they often necessitate special design considerations. For instance: What changes in design must be made when the application requires a pillow block to be installed upside down? What if the bearing load is not applied through the base?

The equipment designer relies on housing static load carrying guidance to make the appropriate selection of pillow block bearing for a given application. Thus, it’s critical that these decision makers have access to housing strength information to optimize the effectiveness of equipment.

The Need for Reliable Housing Strength Data

The demands of today’s operations require bearings to work harder and longer. This means the housing must work harder, too.

Applications that generate more than one loading orientation on bearings require housings that can bear the same loads, hence the need for consistent housing strength data when designing equipment. In these types of applications, housings handle extreme forces in varying directions and allow the bearing to be mounted in positions where the load may not be applied directly through the base.

These orientations are most common in large conveyor systems and in extreme applications like industrial crushing machines or hammer mills.

Spherical roller bearings are commonly used in general industrial applications, providing dependable performance and capacity in supporting radial loads with limited axial loading.

A common question when seeking replacement mounted bearings is: What kind of load can be applied to my bearing? Answering this question is critical to selecting an appropriate bearing for the application. The geometries of mounted roller bearing housings can be complex and varied in shape, based on the size and type of bearings they support, making it complicated to estimate housing strength.

The Timken testing methodology for generating housing strength data combines advanced modeling techniques and experimental testing, all backed by real-world experience for the purpose of providing answers for customers.

Housing Strength Testing Methodology Loads can be applied to pillow block bearings in virtually limitless ways. Testing every housing to failure in every loading orientation is impractical, requiring a consistent modeling technique to maximize available usable data.

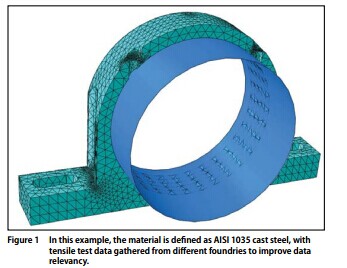

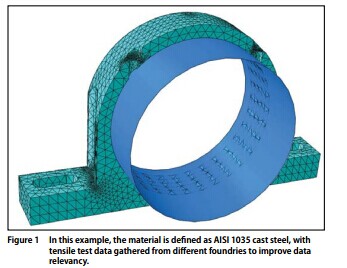

Timken developed a method of generating breaking strength data based on laboratory testing, advanced modeling calculations and the company’s history in the metallurgical engineering field. Finite element analysis (FEA) is combined with experimental testing to create calibrated models that calculate the limiting static strength of the bearing housing. Housing strength design rules were then established and appropriate strength values published.

Modeling/Finite Element Analysis (FEA) FEA is deployed primarily to account for the diversity in mounted bearing housing shapes and complexities. For housing strength, FEA is desirable over simplified analytical expressions’ limits in accounting for complex shapes. FEA can account for the interaction between complex housing geometry and non-linear material properties when calculating stress and strain.

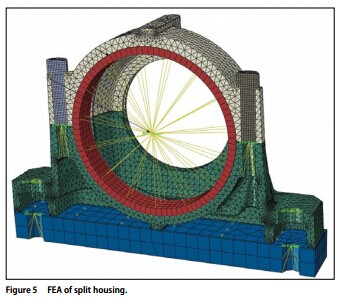

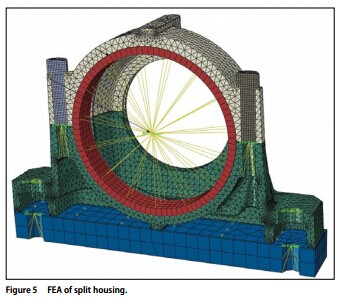

Three-dimensional solid models of housings are prepared as a first step for incorporation into the FEA model. Based on the loading and geometry symmetry, a half model was created to reduce the size of the model and the subsequent solution time. These models were first solved to get a rough estimate of the breaking strength of the test parts to estimate experimental tooling requirements. The models were later refined to include failure criteria validated through experimental results. (Fig. 5)

Cast iron is commonly used for mounted bearing units, desirable for its relative structural rigidity, strength under compression and corrosion resistance. However, some applications require very high impact loads or non-horizontal mounting, where cast iron does not provide adequate strength. Cast steel offers a strong alternative.

It has approximately twice the yield strength as comparable cast iron and offers greater breakage resistance in tougher applications. Ductile iron also far exceeds cast iron in strength and can be advantageous for certain housing geometries.

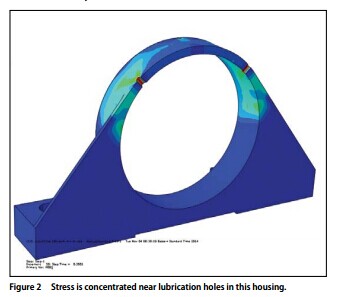

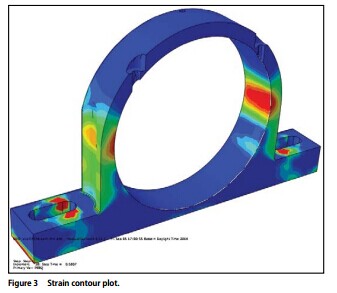

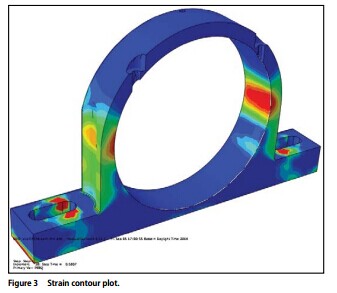

Through FEA modeling, Timken is able to calculate and define accurate fracture strain and stress values. Breaking strength for cast steel housings is estimated with a non-linear elastic-plastic analysis with an isotropic hardening model. Based on the housing’s material properties, ductile damage data is entered into the FEA models to check the maximum strain of each element. As the housing load is increased, the material hardens while elements elongate and exceed critical strain thresholds. The load on the housing reaches a maximum, followed by ductile fracture.

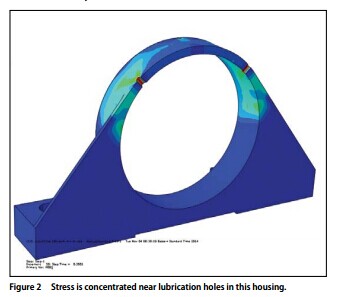

Typical strain patterns are illustrated in Figures 2 and 3. Simulated modeling that follows an established method, as outlined above, allows Timken to predict housing strengths, enabling the customer to create a more reliable and dependable design.

Modeling is only part of the process. Testing is also used to verify the modeling assumptions and provide better and more realistic model parameters.

Physical Testing FEA simulation assumptions were based on findings for housings loaded to the point of fracture. To determine these figures, Timken housings of different sizes were selected and loaded in a hydraulic press outfitted with specialized universal tooling then tested at a range of loads.

The universal tooling used for these experiments is able to break housings in 180-, 150- and 90-degree loading directions based on differing setup configurations, reflective of the unconventional angles in which pillow blocks are installed in the real world. Since the estimated load necessary for housing fracture in these simulations could exceed the bearing static limit, no bearings were used in this exercise. Instead, they were replaced with round bars. Various styles of solid block housings and split block housings were physically tested.

Each test was performed using properly controlled loading cycles. Hydraulic fluid was slowly metered into the load piston using a control valve. A computer recorded the values of the load cell throughout the test so the maximum loads could be determined.

Multiple replicates were tested in each of the loading directions. The results of the test indicated variability between the replicates in load magnitude as well as breaking location. For example, a four bolt housing had three different failure locations when loaded in the 180-degree direction. The attachment bolts through the base flange had to be supported in each test to prevent bolt breaking and force a housing break. This was necessary even when using Grade 9 quality bolts.

The housing break failures, as seen in Figure 6, were ductile in nature, as demonstrated by the visible deformation in the housing before fracture occurred. These results were consistent with the expectations for cast steel material and assumptions based upon FEA findings. Large plastic deformation was seen at the bolt attachment area on the flanges, though no ultimate fractures occurred there. Breaking load, displacement and break location data were collected from each test.

The methodology for analyzing and testing split housings was similar to that of solid housings. The testing showed that the gray cast iron housings had a more brittle failure mode with little deformation before fracture. Breaking loads were lower than the cast steel due to the material strength difference. The ductile iron housings had larger strains than the gray iron at fracture, but not as great as the cast steel parts. (See Fig. 6.)

In the FEA, the gray cast iron housing failure criteria were defined using an extended fracture mechanics model. In comparison, the ductile iron housings used the same failure model as the solid block housings, but with a smaller fracture strain definition. The split housings also introduced another failure mode, which was bolt fracture on some of the housings. To account for this, FEA models were enhanced to include bolt ductile damage failure criteria. (See Fig. 5.)

Housing Strength Test Results

The Timken methodology for determining housing breaking strength can help equipment designers and end users make informed decisions on the advantages and benefits of each of Timken’s housed units. Through this rigorous testing process, Timken established not just the strength of its materials, but also the unique applications in which its portfolio of mounted bearings and housings will best perform, backing housing strength estimates with conclusive data.

Failure modes may vary based on casting geometry, casting material, and cap bolt size and grade. Split housings enable a simpler assembly and can help reduce overall installation cost, but do not maintain the same overall strength of comparable single-piece, solid block housings. Solid cast steel housing strength values generally exceed the bearing capacity regardless of load direction. Using a conservative approach, published housing strength values for solid block housed units were established using minimum material properties.

Gray cast iron generally has a smaller load-carrying capacity at varying orientations than ductile cast iron. While gray cast iron can be a more cost-effective material than ductile iron, it may not be the appropriate choice for more demanding applications in non-horizontal load bearing applications.

Easy-to-use safe load guidelines for Timken split housings, where load is not applied directly into the base or if the base is unsupported (P0) have been developed. The safe load is the maximum suggested load to be applied to the housing depending on the direction of the load. The safe load guidelines for split housings account for the breaking strength of the housing and the breaking strength of the cap bolts.

A commonly accepted safety factor of five is used for the breaking strength of the split housing material, and a safety factor of three is used for the cap bolt breaking strength. Additional safety factors may be applied by the user for safety-critical applications.The published safe load values assume the housing has been properly secured to the base structure and proper torque has been applied to the cap bolts.

Figure 7 shows a comparison of housing safe loads for both cast iron and ductile iron relative to shaft size and angle of the applied load. This shows the importance of housing design and material selection in selecting the proper housing for a given application.

By using FEA results calibrated with experimental testing, Timken has created a methodology to predict housing strength without testing each unit.

Through this combination of advanced modeling and realworld experience, Timken is able to provide estimated housing strength of its mounted bearing offerings. Actionable, accessible data is one more way Timken meets the increasing demands of heavy industry every day.

Industry News

Industry News