NSK Ltd. (NSK; Headquarters: Tokyo, Japan; President and CEO: Toshihiro Uchiyama) today announced that it has developed 6th-generation low-friction tapered roller bearings for automotive transmissions. The new tapered roller bearings have even lower friction and will contribute to higher automotive fuel economy. NSK is targeting 2 billion yen in annual global sales of this new product in 2022.

NSK Develops 6th-Generation Low-Friction Tapered Roller Bearings for Automotive Applications

Development Background

There is a need to reduce friction in rolling bearings used in transmissions in order to improve transmission efficiency, which in turn helps to improve automotive fuel economy. Generally, ball bearings or tapered roller bearings are used for the rolling bearings that support the transmission shaft. Thus, the important issue is to find a way to reduce the friction of tapered roller bearings, which tend to have a lot of friction compared to ball bearings.

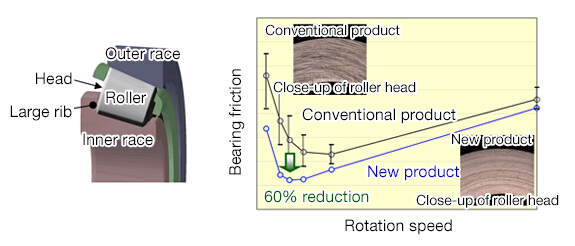

In tapered roller bearings, rolling friction is produced between the roller surface and the raceway of the inner and outer rings; sliding friction is produced between roller heads and the large rib of the inner race; and further friction is produced by agitation resistance in the lubricating oil. Since 1980, NSK has been developing tapered roller bearings that reduce these kinds of friction. Over the first five generations, NSK reduced friction loss by 60 percent.

However, to meet the social need for improved fuel economy, which has been growing more and more in recent years, there was a need to develop even better low-friction technology for tapered roller bearings.

Product Features

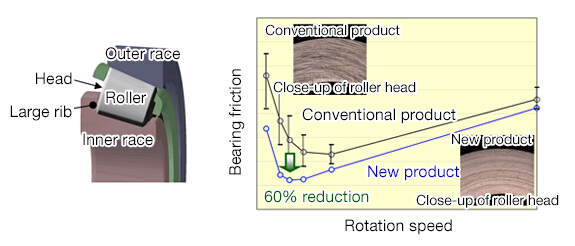

When tapered roller bearings rotate at a low speed, the sliding friction produced between the roller heads and the large rib has a large impact on friction throughout the bearing. The newly developed product improves this, thereby reducing friction without affecting the other functions of tapered roller bearings.

1. Lower friction

By improving the surface roughness of the roller heads and the large rib, friction was reduced by up to 60 percent at low speeds and up to 20 percent on average for all rotation speeds.

2. Larger effect in a low-viscosity oil environment

In recent years, the use of low-viscosity lubrication oil in transmissions has increased in order to reduce agitation resistance in lubrication oil. The newly developed product's effect is even more pronounced when low-viscosity oil is used.

Product Benefits

This bearing reduces friction compared to the conventional bearing, and will thereby contribute to improved fuel economy.

Industry News

Industry News