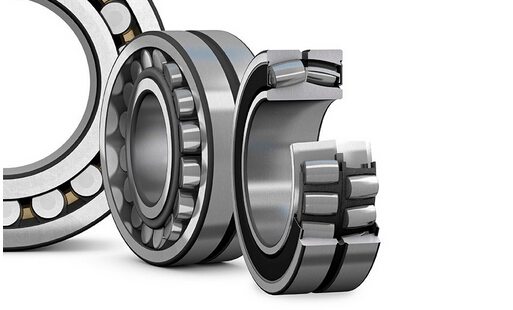

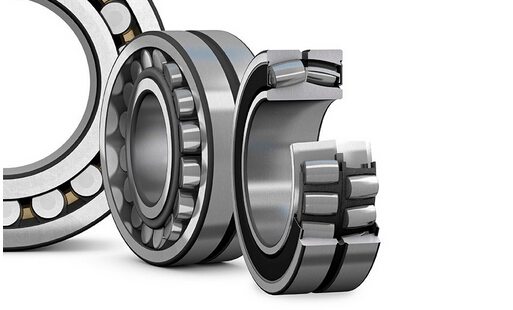

SKF has taken a strategic decision to shift its global business focus back to the company’s core strength – bearings.

As a leading global technology provider since 1907, SKF has over the years developed a holistic product and service offering that is integral to bearing performance and reliability. “Since 2007, we have been placing our energy into seals, lubrication, power transmission, mechatronics, condition monitoring and engineering service solutions to support our quality bearing range, and this we have done with great success,” says SKF Services and Solutions Manager for Southern Africa, Sarel Froneman. “But we may have been too successful, losing focus on what is fundamental to our rotating technology solutions namely our bearings.”

According to Froneman, there are customers who have standardised on SKF’s products and systems that do not necessarily use SKF bearings. He cites one such example of a local coal mine that has standardised on SKF’s condition monitoring systems yet their crushers, conveyors, electric motors, gearboxes, etc. may not necessarily be equipped with SKF bearings. “So while the mine is a key SKF customer, they may never have placed an order with SKF for our core product!”

While SKF continues to hold its solid reputation as a leading supplier of quality bearings, SKF CEO, Alrik Danielson believes that SKF must once again become the world’s number one bearing company. “Our mandate is therefore to raise the profile of SKF bearings across all our product and services offerings,” states Froneman. “Our bearing offering should remain our number one priority and common denominator of all our rotating technology products and services.”

“This having been said, we must not lose sight of the fundamental role of our application engineering and asset management service solutions.” SKF’s application engineering is an integrated range of products designed to support the integrity of rotating machinery, the most critical components being bearings.

Froneman explains that application engineering usually deals with more complex requirements such as upgrades and customisations and may involve an investigation of the bearing for example. In consultation with the customer, the application engineering team can develop a complete and optimal rotating technology solution with bearings at the core. The SKF application engineering team’s capabilities extend to modifications of standard products such as the manufacture of special sealing arrangement, changes to bore-sizes on standard couplings, etc. Froneman adds that his team can also modify entrances for condition monitoring or lubrication services.

Bearing remanufacture is another key function of SKF’s application engineering. “Our basic remanufacturing service can restore unused bearings that have passed their shelf life to ‘as new’ at approximately 15% of the cost of a replacement bearing. For bearings that have been in operation, we offer a full Level 4 remanufacturing service. Alongside substantial savings on cost compared to a new replacement unit, remanufacturing also offers the advantages of fast turnaround times and a reduced carbon footprint as less new steel is required.”

SKF’s asset management services embrace maintenance solutions based on asset criticality geared to minimise the risk of failure by optimising equipment reliability and subsequent equipment life for maximised uptime. This move underlines the new SKF Group vision – ‘a world of reliable rotation’ and demonstrates the company’s understanding of what customers ultimately want - improved productivity and lowest possible ownership costs through reliable equipment performance and extended equipment life.

In conclusion Froneman states that it is not about selling as many bearings as possible. “Bottom line, by adding value through offering holistic rotating technology and service solutions, we build long-term customer partnerships.”

Industry News

Industry News