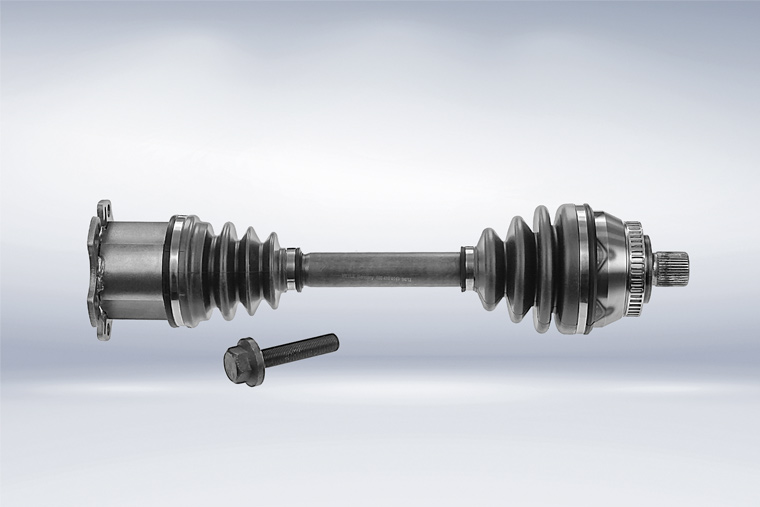

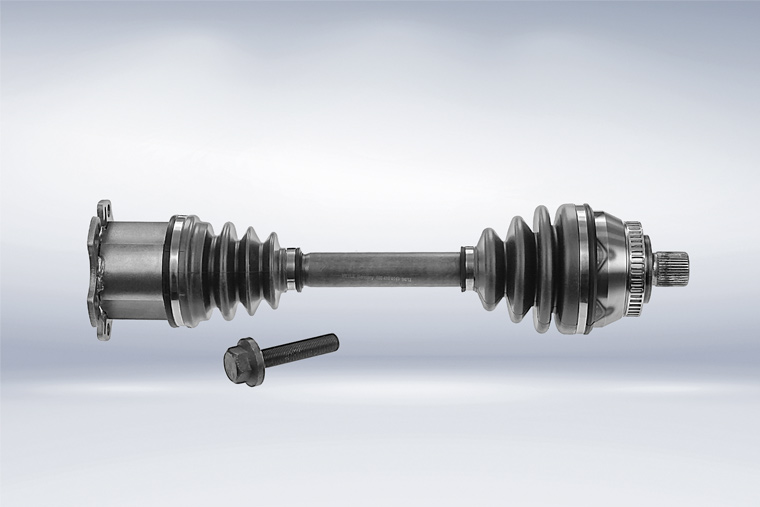

Drive shafts generally have to endure very high load levels during operation. In order to help workshops cater better to the quality requirements of their customers, MEYLE has added another 100 new drive shaft units to its current range.

Drive shafts are directly exposed to the loads that are created in the gearbox and hence normally, customers are very particular about the quality of drive shaft design. In addition to the loads, the drive shaft joints and boots are also subject to the vehicle’s compression and rebound forces. Drive shaft boots undergo abrasion during the high load levels when the vehicle is being driven and this can make the rubber tear. When the rubber tears, the grease needed to provide sufficient lubrication will leak out and contaminants and moisture seep in. The 100 new drive shaft units that Hamburg based manufacturer MEYLE is offering will complement its existing range and have been designed to meet the highest demands.

MEYLE-ORIGINAL drive shafts are fashioned from forged steel that has been specially chosen for the application. The grease that has been used also has been specially formulated to withstand the exceptional requirements and strain levels that will be acting on the joint. The retaining latches have genuine original-equipment quality and ensure that the boots fit securely. Each MEYLE-ORIGINAL drive shaft undergoes pre-defined in-process testing and evaluation and can be safely relied upon by all repair professionals and motorists.

Industry News

Industry News