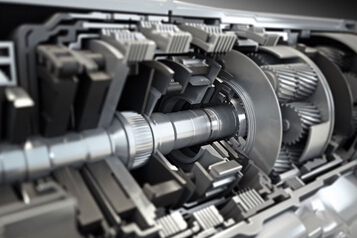

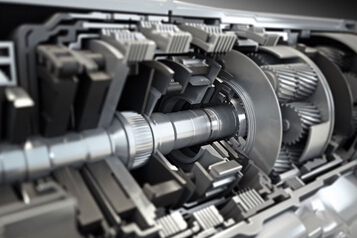

Weinheim (Germany), January 9, 2017 – The sleek vehicle styling on display this week at the North American International Auto Show (NAIAS) in Detroit is bound to generate excitement. But the sophisticated new powertrain technologies that manufacturers are incorporating under the hood are equally deserving of notice. Efforts to produce cleaner, more powerful cars and trucks have led to the industry’s ongoing adoption of concepts such as downsizing, turbocharging and development of high gear transmissions.

Speed Transmission

As vehicle manufacturers incorporate such state-of-the art technologies, Freudenberg Sealing Technologies is matching their pace with process and product solutions that address improved fuel economy, lower emissions and smaller, tighter spaces.

With the recent introduction of one major manufacturer’s 10-speed transmission program, for example, Freudenberg is playing an important role in supplying this customer with access to new materials and new processes that are quality driven and focused on weight and emissions reductions.

Freudenberg’s 10-speed transmission program incorporates a number of unique processes and components that will drive new technologies across the organization. Among those innovations are a lightweight front cover housing with integrated seals, an automated vision control inspection system and PTFE-coated O-rings that improve assembly capabilities and part traceability.

“Working with our customers on significant technology programs has allowed Freudenberg to introduce many important new innovations across its facilities,” said Matthew Chapman, Vice President of Automotive Marketing, Freudenberg-NOK. “We are proud to support such cutting-edge programs by leveraging new technical capabilities that address crucial component issues like weight, quality and durability.”

Lightweight alternatives

Fuel economy and better performance are the name of the game in today’s cars and trucks, and lightweight components that contribute to this goal are essential to vehicle manufacturers. Recently, Freudenberg began providing 10-speed front cover modules with integrated seals for easier assembly, improved quality and lighter weight.

The plastic carrier gaskets for the front cover modules are being supplied by Freudenberg’s Gaskets Lead Center facility in Manchester, NH. The plant is preparing production capacity to support customer transmission programs over the coming years.

The company’s expertise in working with plastic carrier gaskets and injection molding allowed it to successfully replace the traditional metal plate design with a highly engineered plastic carrier plate onto which a FKM elastomer seal is molded.

Integration of the FKM seal onto the plastic carrier plate reduces the chance of final assembly errors by eliminating the possibility that a separate O-Ring would become dislodged during assembly.

The front cover module also incorporates one of the company’s radial shaft seals from its Cleveland, GA., facility.

Manchester has introduced new technology for injection molding onto the plastic carrier plate. Importantly, because plastic flexes when under pressure, the company had to develop technology that would ensure the component held its tolerances when inserting the radial shaft seal to complete assembly of the front cover module. Freudenberg uses an adjustable core technology in the injection molding process that ensures the carrier plate meets the tight tolerances and holds its shape.

A visual aid

Freudenberg’s Transmission and Driveline Lead Center in Cleveland, Ga., has invested in state-of-the-art Automated Visual Control (AVC) system that improves the quality and reliability of the radial shaft seals being delivered to customers. Freudenberg’s AVC system is internally developed and its capabilities exceed those of commercially-available solutions.

The plant’s AVC uses automated visual inspection and laser etching to automatically check parts for many different defects which cannot be seen through normal vision inspection. It also etches a serial number onto each one. This automated inspection system helps ensure that all seals leaving the plant meet the highest specifications. It also gathers data that helps improve manufacturing efficiency and achieve extraordinary results in terms of product geometry and manufacturing tolerances.

The AVC system relies upon active and dynamic statistical process control at the point of manufacturing. Seals are automatically examined and component-specific data is collected and retained, making product analysis and traceability possible long after the part has been in the field. This innovation system provides higher value while eliminating the risk that nonconforming components will reach the end customer.

The AVC system in use in Cleveland is best-in-class for polymer-based surface inspection. Defect detection is variable and assignable with severity; further, the system can detect defects orders of magnitude better than commercial systems. Traceability and serialization are integral to the vision system, functioning seamlessly in process with production and provide a superior tool for process optimization in real time.

A better assembly process

Freudenberg’s LaGrange, Ga., O-Ring Competence Center is using all new technologies to supply auto manufacturers’ 10-speed transmission with state-of-the-art injection molded components. These large diameter, color-coded, D-shaped O-Rings are helping LaGrange push its manufacturing capabilities to a new level through cooperation with Freudenberg Sealing Technologies’ O-Ring Lead Center in Oberwihl, Germany and NOK Corp. in Japan.

The D-shaped O-Rings being supplied are lathe cut, and the plant has worked to improve the entire process in order to reduce engineered waste, increase productivity and produce a more consistent product. After molding, post cure and cutting the D-Rings, the parts are taken to an internal coating area where they are coated with a PTFE stripe.

The striping process is new to the LaGrange facility. The PTFE stripe helps with alignment during installation and lessens the force needed to install the D-Rings on the transmission assembly.

LaGrange made a significant investment in new coating equipment, new lathes and new presses to produce the components in sufficient volume and quality to ultimately support the industry’s push to new transmission designs. A laser measurement system was also introduced into the process to ensure that every D-Ring cut by the lathe is accurate. The new process incorporates a variety of innovations including new tooling that improves the quality of the finished components.

Industry News

Industry News